News

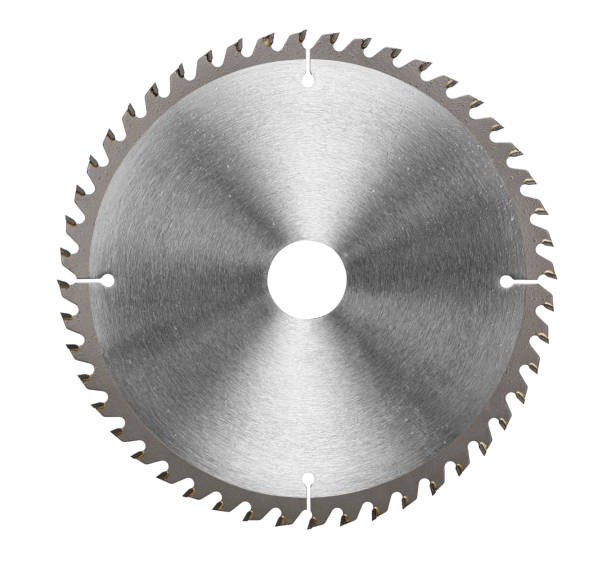

Causes and solutions to common problems in saw blade use

1. Wear at the joint between the base and the cutter head

Reason: The material being cut is very wear-resistant, and the cutting debris is mixed in the cutting seam and cannot be discharged.

Solution: Use protective teeth at special positions on the base body and use cooling water flow with higher pressure to enhance chip removal effect.

2. Uneven wear on both sides of the cutter head

Cause: The saw blade is cutting at an angle; the amount of water on both sides is different, and there is insufficient water on one side.

Solution: Check the tilt of the saw blade; check the cooling water system.

3. Saw blade out of round

Cause: Shaft wear causes a large gap between the saw blade center hole and the spindle or incorrect installation.

Solution: Replace the worn shaft or repair the center hole.

4. Saw blade deflection

Causes: The debris of the cut material is mixed in the cutting seam, causing uneven force on the machine body; the diameter of the flange is too small or the diameters of the flanges on both sides are inconsistent; there are foreign objects between the saw blade and the flange; it is not installed correctly.

Solution: Clean up the debris and improve the chip removal effect; adjust or replace the flange; install it correctly according to the instructions.

5. Broken blade

Cause: The blade bond is too hard; the saw blade feed speed is too fast.

Solution: Choose a saw blade with a softer bond according to the material being cut; reduce the feed speed of the saw blade.

6. The cutter head wears too quickly

Causes: The blade bond is too soft (for the material being cut); insufficient cooling water; insufficient power due to loose drive belt, low voltage or inappropriate speed; the saw blade is not perpendicular to the material being cut.

Solution: Choose a saw blade with a harder bond according to the material being cut; check the cooling water system to ensure that the water pump is operating normally; ensure the power supply voltage; check the spindle flange to ensure the verticality of the saw blade and the equipment; check the saw blade speed.

7. Loss of blade

Causes: During the cutting process, the material being cut slides and twists the cutter head off; the cutter head is hit hard; the flange is worn and cannot fix the saw blade, causing the saw blade to twist; the saw blade is out of round due to spindle wear, causing the saw blade to be subjected to a large impact; overheating; the saw blade is subjected to a violent impact.

Solution: Secure the material being cut firmly during cutting; replace the flanges on both sides; replace the worn spindle; check the cooling water; avoid hitting the saw blade when moving the equipment or the material being cut.

8. Blunt and unable to cut

Causes: The saw blade bond is too hard; insufficient power can not make the saw blade cut normally, the saw blade is not applied with enough cutting pressure; the saw blade linear speed is too high.

Solution: Choose a saw blade with a softer bond; check the drive belt, voltage, and motor; make sure that sufficient but not excessive cutting pressure is used; and select a saw blade with the appropriate diameter according to the equipment's manual.

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Lily Tang

Tel: 0086 13812228944

E-mail: info@baolisaw.com

Add: Jinglin Industrial Park ,Jinling East Road ,Danyang City,Jiangsu Province, China

English

English Pусский

Pусский Lily Tang

Lily Tang